DC casting automation

TDC casting automation is ensured by PAE Technologies’s renowned automation system, AUTOPAK®. This is generally supplied with the casting trough (equipped with Metal Level Control sensors and actuators) and, if the customer so desires, with the DATA MANAGERTM and supervision systems. This advanced technology is integrated in PAE Technologies’s own vertical DC casting machines, but can also equip other machines for upgrading purposes. With this technology you can be sure of accurate, flexible and safe casting of premium metallurgical quality.

For most ingot formats, PAE Technologies expertise covers all families of aluminium alloys (e.g. soft or hard alloys, alloys with high magnesium content) and all applications, including those for the aerospace industry. Additionally, PAE Technologies offers associated services such as technical expertise, design, software development, supply of components (such as digital actuators and digital-capacitance type metal level sensors), spare parts, and consumables.

Premium metallurgical quality

High quality ingots are guaranteed by the accuracy, reliability and repeatability of the casting process controlled by the AUTOPAK® system. The DATA MANAGER TM system monitors and analyzes casting data and parameters.

Flexible production

Production flexibility is enabled by the possibility of casting different formats within the same drop and by the system’s ergonomic features.

Hands-off casting

Casting control

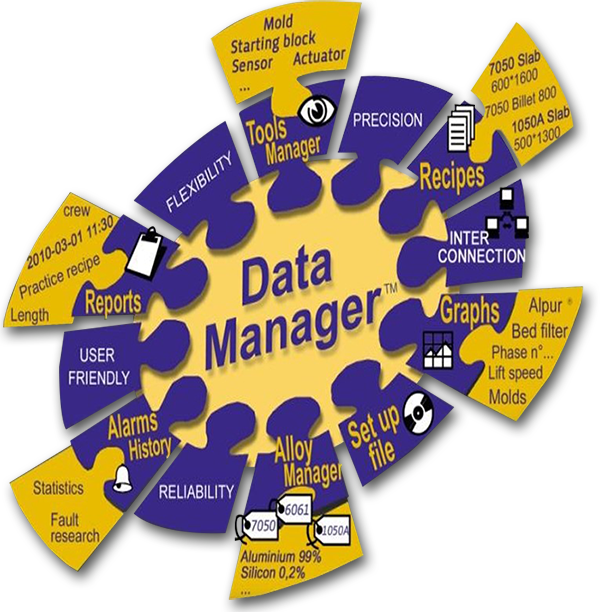

The casting control system is equipped with a user-friendly and ergonomic interface and includes the DATA MANAGERTM system that ensures the management and analysis of casting data, such as:

- Creation and revision of the casting recipe depending on the requirements of the metallurgists

- Preparation, sending, and printing (if required) of casting reports plus back-up with traceability of changes

Other examples are shown in the following diagram

The powerful Data Manager TM software for casting lines – based on SQL database

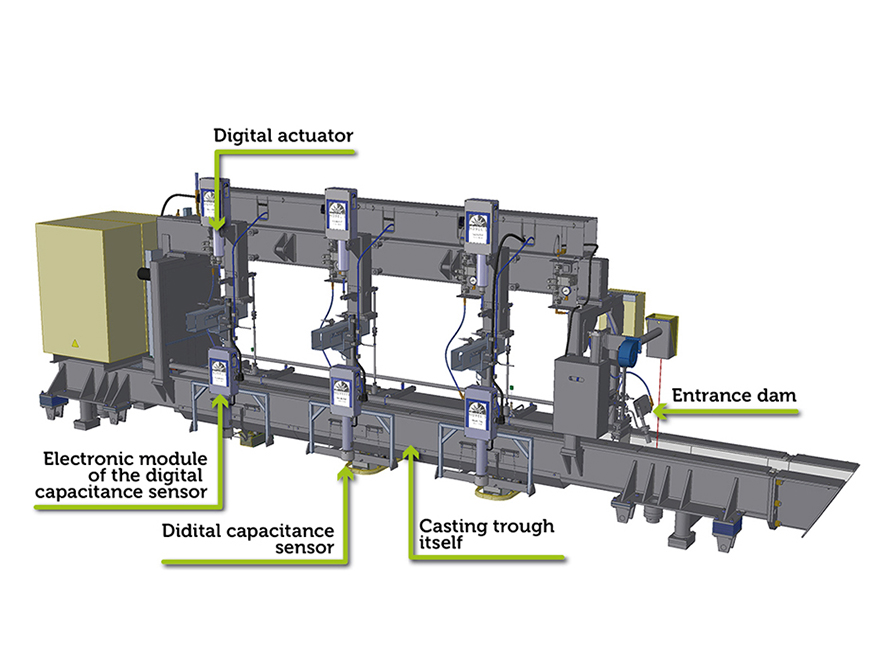

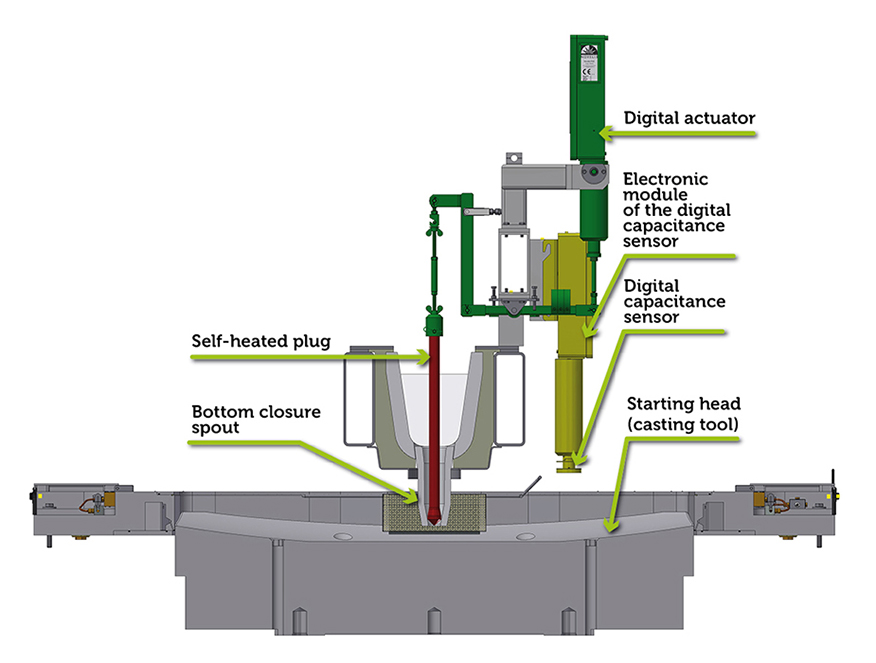

Metal Level Control system

- Bottom closure spouts, one per casting strand, each fitted with a self-heated plug. The level of the plug is adjusted by a digital actuator according to the required flow rate of the liquid metal

- Metal Level Control sensors of the digital capacitance type (or other type on request) whose measurements are entered in the P.I.D. regulation loops to control the position of the above mentioned plugs.

Data Manager – Casting controls (selection)

| Base | Functions | Key parameters of the casting line | |

| Production control | Alloys Manager | Type, composition of each alloy | |

| Recipes | Parameters of product type (alloys, size…) to ensure quality | ||

| Reports | Parameters used and events during each cast, information that could be used to improve quality | ||

| Machine control | Tools Manager | Mold, starting block, sensor, actuator… | |

| Alarms History | Statistics, fault research | ||

| Graphics control | Equipment: Tracking and tuning | ||

Supervision system

It ensures the online follow-up of the cast, with a wide range of screen views and applications. The system can be connected with other PCs on site, while remote support is provided by the PAE Technologies office.

AUTOPAK®

This automation system controls all the sequences in the casting phases and all associated parameters from the furnace interface, through the upstream equipment (Rod Grain Feeder, etc…) to the casting machine. The main functions controlled are as follows:

- Mold filling sequence

- Mold level control during steady state regime

- Detection of casting failures such as bleed-outs and hung plates

- Casting speed control

- Cooling water flow control

- Handling of casting trough

What you get

when you choose

the PAE Technologies

DC casting automation:

- The product of a wealth of experience and technological leadership

- PAE Technologies’s ability to design and supply the whole casting line (located downstream of the holding furnace): degasser, filtering unit, launder system, casting machine

- 60 years of experience serving aluminum casthouses

- Unique engineering know-how to match your specific needs and requirements

- Technological advantages, resulting from our first class innovation policy

- Extensive operational experience and a real understanding of the needs of users, helped by the fact that our own group is among them

- First-class customer support and service worldwide