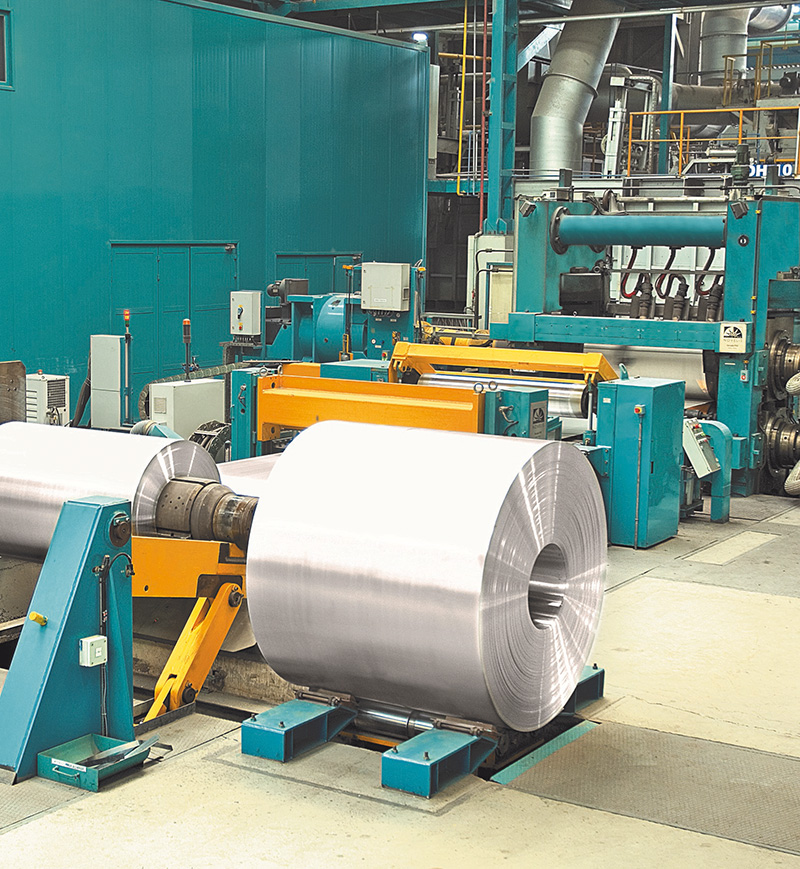

Twin-roll casting machine

BENEFITS OF CONTINUOUS STRIP CASTING VS HOT ROLLING

On-site scrap processing

All scrap can be recycled into value-added products.

Modular investment and flexible operation

Production capacity can be progressively increased to keep pace with market demand.

Low capital and operating costs

A continuous caster performs an all-in-one process that replaces DC casting, scalping, sawing, preheating and hot rolling. This short process reduces capital and conversion costs, including manning and energy.

Short lead-time

As a single-step process, continuous casting produces strips from molten metal in a shorter time compared with conventional processing routes. This enables a rapid response to customer demand and reduces inventory

Wide range of capabilities

Jumbo 3C – 3CM® casters

500 – 620 – 840 – 960 – 1150

Up to 2500 mm

3 to 12 mm

Up to 30 tons

Up to 30 000 t/year

Wide range of capabilities

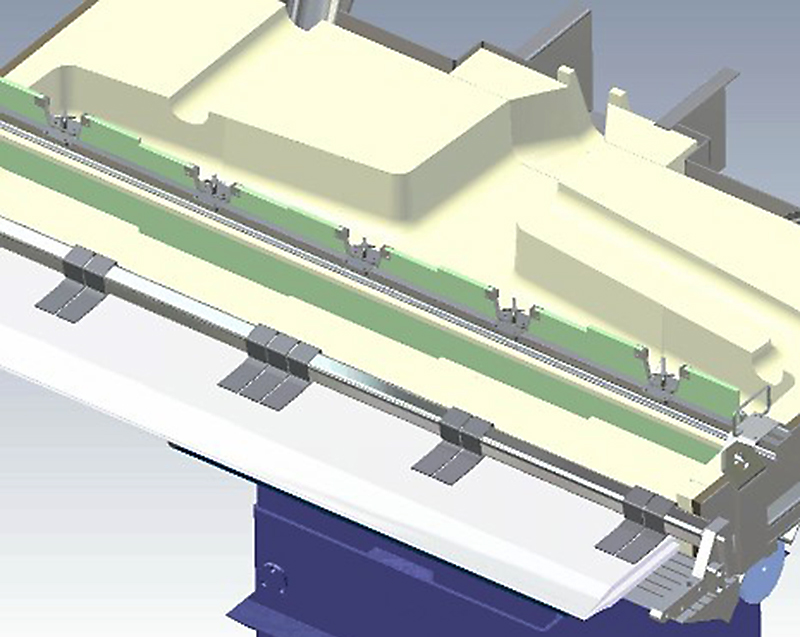

The control of metal feeding in terms of metal level, flow and temperature distribution throughout the width of the strip is critical to guaranteeing the required strip gauge and profile quality.

PAE Technologies has designed a metal feeding system that enables the operator, during the casting process, to adjust the flow of metal in the tundish before it enters the tip.

The tip position can be adjusted with precision in every direction thanks to the tip table mounted on the floor. An appropriate gap is maintained between the tip lips and the rolls to avoid any touching.

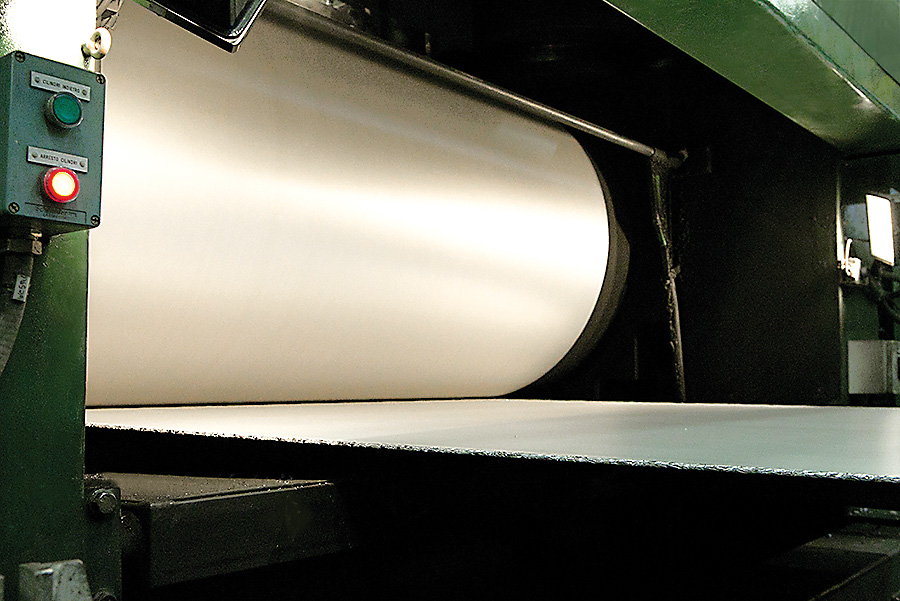

Roll lubrication and coating control

The roll spraying technology used is a key feature in controlling the roll/metal interface and therefore the surface quality of the as-cast strip.

A good lubricant application on the rolls leads to a lower consumption of release agent and improves caster performance: better surface quality, higher casting rate, improved geometrical tolerance.

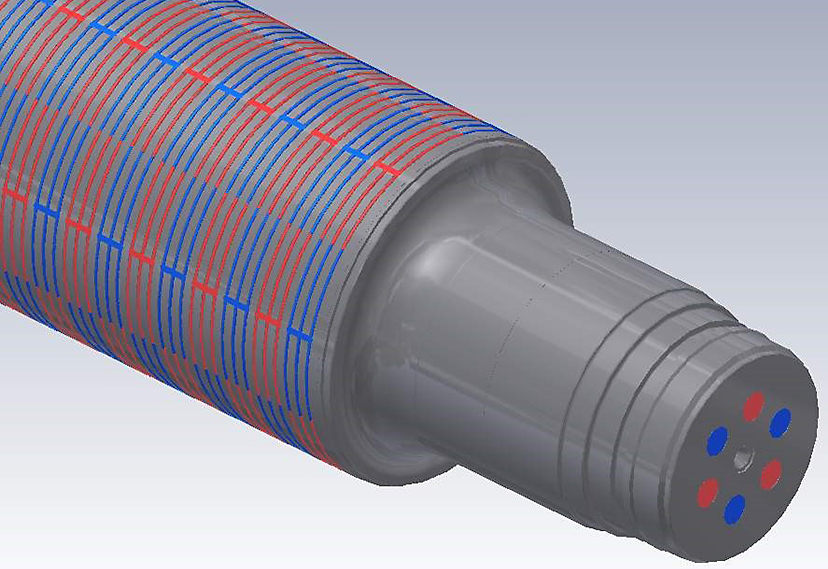

Caster roll cooling technology

PAE Technologies roll design guarantees uniform cooling across the width and over the circumference as well as a maximum heat extraction rate in order to maximize the casting rate.

The patented checkered cooling pattern, based on extensive numerical modeling, is available in a 4-hole or 6-hole configuration.

What you get when you choose the PAE Technologies twin roll caster:

- The product of a wealth of experience and technological leadership

- PAE Technologies’s ability to design and supply the whole casting line (located downstream of the holding furnace): degasser, filtering unit, launder system, casting machine

- 60 years of experience serving aluminum casthouses

- Unique engineering know-how to match your specific needs and requirements

- Technological advantages, resulting from our first class innovation policy

- Extensive operational experience and a real understanding of the needs of users, helped by the fact that our own group is among them

- First-class customer support and service worldwide