DC casting machine

PAE Technologies designs, manufactures and commissions complete vertical DC casting machines, including their casting tools and casting automation system (AUTOPAK®, DATA MANAGER TM & supervision). PAE Technologies know-how can also be used to upgrade existing machines. For each project, the scope of supply and services is adapted to the customer’s needs.

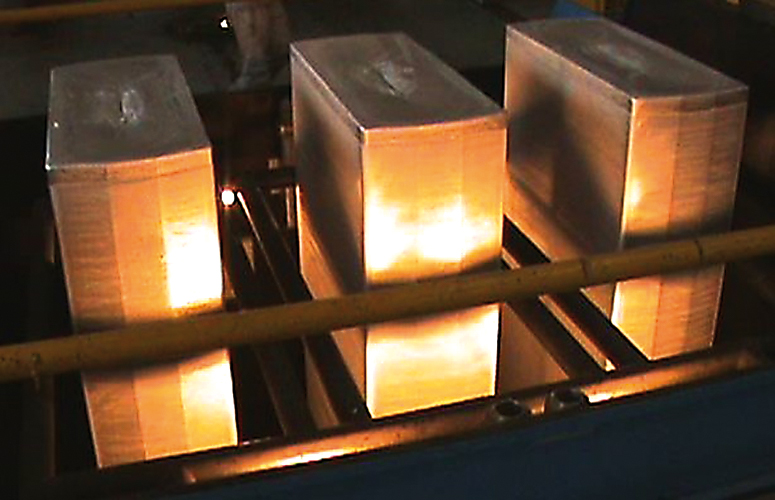

You can be sure that our leading-edge technology will provide you with accurate, flexible and safe casting of premium metallurgical quality. For most ingot formats, PAE Technologies expertise covers all families of aluminium alloys (for instance: soft, hard, with high magnesium content) and all applications, including those for the aerospace industry.

Premium metallurgical quality

Flexible production

This flexibility is made possible not only through the casting of different formats within the same drop, thanks to the functions offered by AUTOPAK®, but also through the technology of the casting tools (variable molds and, for soft alloys, variable starting heads).

Safety first

The high level of automation and reliability enables “hands-off” control during the whole casting process (start-up, steady state, termination), thereby enhancing safety.

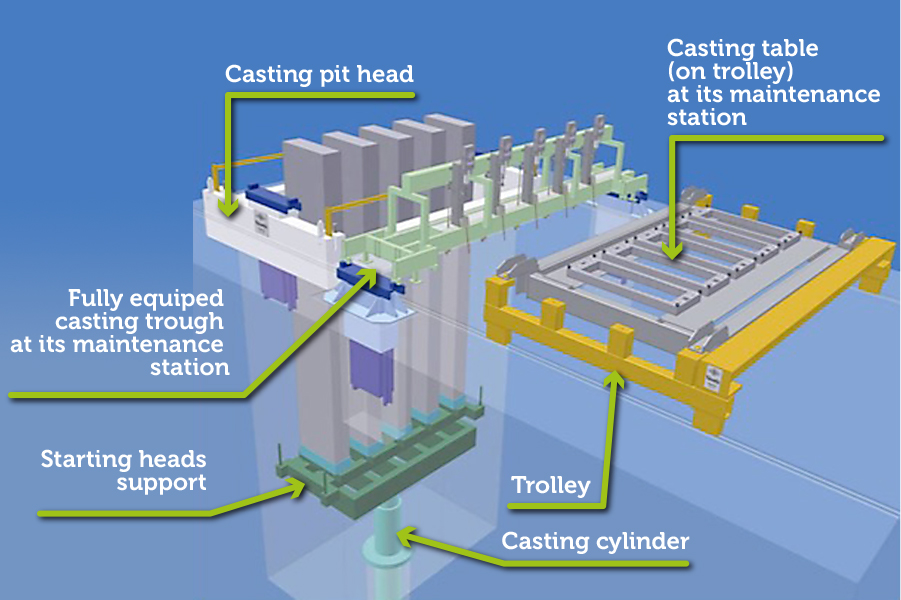

Layout of the DC casting machine

The typical layout of the PAE Technologies DC Casting machine affords easy access for preparation processes and user-friendly maintenance. The layout includes three main positions:

- The casting pit equipped with the pit head, above which the casting table is positioned for casting operations

- The maintenance station of the casting trough

- The maintenance station of the casting table

One trolley is used to transfer the casting trough and casting table from the casting pit to their respective maintenance positions and then to return them to the casting pit before a new cast.

What you get

when you choose

the PAE Technologies

DC caster:

- The product of a wealth of experience and technological leadership

- PAE Technologies’s ability to design and supply the whole casting line (located downstream of the holding furnace): degasser, filtering unit, launder system, casting machine

- 60 years of experience serving aluminum casthouses

- Unique engineering know-how to match your specific needs and requirements

- Technological advantages, resulting from our first class innovation policy

- Extensive operational experience and a real understanding of the needs of users, helped by the fact that our own group is among them

- First-class customer support and service worldwide